Range of ceramic cartridge headworks with plastic bodies for insertion into specifically dimensioned tap assemblies. Some models incorporate a stainless-steel strainer. Maximum working pressure 16.0 bar. Maximum operating temperature 85°C.

Single hole, single outlet (fixed) combination tap assembly (brass bodies – various finishes). Incorporating quarter turn ceramic disc headworks with single lever operating members. The spout is a pullout hose and handset with an optional spray function. The outlet incorporates a plastic aerator. Maximum working pressure 10.0 Bar Maximum operating temperature 65.0°C

Range of single-hole, single outlet (fixed) combination tap assemblies (chrome plated brass bodies) incorporating ceramic cartridge headworks with single lever operating members. The spout outlets incorporate plastic aerators. The ‘2920’ models are supplied with a lever operated pop-up waste. The inlets incorporate plastic strainers. SECURITHERM EP BIOSAFE models also incorporate approved single check valve cartridges, however, the complete product has not been fully tested to demonstrate it provides backflow protection. Maximum working pressure 5.0 Bar Maximum operating temperature 60.0°C

Range of single hole, single outlet fixed combination tap assemblies (brass bodies - various finishes) incorporating quarter turn ceramic disc headworks with dome type operating members. The temperature is controlled via a thermostatic mixing cartridge with a dome type operating member. The spout outlet incorporates an aerator. The inlet hoses each incorporate a stainless-steel strainer and an approved check valve cartridge however, the complete product has not been fully tested to demonstrate it provides backflow protection Maximum working pressure 10.0 Bar. Maximum operating temperature 60°C.

Range of single hole, single outlet (fixed) combination tap assemblies with (brass bodies - various finishes), incorporating ceramic cartridge headworks and dome type operating members. The spout outlets incorporate a plastic aerator. Maximum working pressure; 5 Bar Maximum operating temperature 65°C

Range of single hole, single outlet (fixed) combination tap assemblies (chrome plated brass bodies), incorporating a ceramic cartridge headworks with single lever operating member. The spout outlet incorporates a plastic flow straightener. Maximum working pressure 5.0 Bar. Maximum operating temperature 60°C.

Single hole, single outlet (fixed) combination tap assembly (chromium plated brass), incorporating a single sequential cartridge headwork and single lever operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C.

Range of single hole, single outlet (fixed) combination tap assemblies, (brass bodies – various finishes). Incorporating a single sequential headwork with a single lever operating member. The spout outlet incorporates a plastic aerator and the product is supplied with a pop-up waste. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Single hole, single outlet fixed combination tap assemblies (chrome plated brass), incorporating a ceramic cartridge headwork with a single lever operating member. The spout outlet incorporates a plastic aerator. The product is also supplied with a click type pop-up waste (verified by test). Maximum operating pressure 5.0 bar. Maximum operating temperature 65°C.

Range of single hole, single outlet (fixed) combination tap assemblies (brass body, various finishes - see model) incorporating a ceramic cartridge headwork with a single lever operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 bar. Maximum operating temperature 65°C.

Range of floor mounted single hole, single outlet (fixed) combination tap assemblies (brass bodies - various finishes), incorporating a ceramic cartridge headwork with a single lever operating member and a self-cancelling diverter to shower outlet. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C.

Range of floor standing, single hole, single outlet (fixed) combination tap assemblies (brass bodies - various finishes), incorporating a ceramic cartridge headwork with a single lever operating member and a self-cancelling diverter to a shower outlet. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies - various finishes). Incorporating ceramic cartridge headworks with single lever operating members. The spout outlet incorporates a plastic aerator. Maximum working pressure 8.0 Bar Maximum operating temperature 60.0°C

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies – various finishes), incorporating ceramic cartridge headworks with single lever operating members. The spout outlets incorporate plastic aerators. The products are supplied with stainless-steel braided PEX lined connecting hoses and metal back nuts. Maximum working pressure 5.0 Bar Maximum operating temperature 60.0°C

Range of single hole, single outlet (swivel) combination tap assemblies (various finishes). Incorporating ceramic cartridge headworks and single lever operating members. The spout outlets incorporate plastic aerators. Maximum working pressure 8.0 Bar Maximum operating temperature 60.0°C

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies – various finishes). Incorporating a ceramic cartridge headwork with a single lever operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C.

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies - various finishes), incorporating ceramic cartridge headworks with single lever operating member. The spout outlet incorporates a plastic flow straighener. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies - various finishes), incorporating quarter turn ceramic disk headworks with single lever operating members. The spout outlet incorporates a plastic flow straightener. Maximum static pressure 5.0 bar. Maximum operating temperature 60°C

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies - various finishes), incorporating ceramic cartridge headworks with single lever operating members. The spout outlet incorporates a plastic flow straightener. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Single hole, single outlet (swivel) combination tap assemblies (chrome plated brass body), incorporating ceramic cartridge headworks with single lever operating members. The spout outlet incorporates a plastic aerator. Inlets incorporate isolation valves that incorporate single check valve cartridges, however, the complete assembly has not been fully tested to demonstrate it provides backflow protection. Maximum static pressure 5 bar. Maximum operating temperature 60°C

Range of two hole, single outlet fixed combination tap assemblies, (brass bodies – various finishes) incorporating a push to open and push to close headwork. The spout outlet incorporates a plastic aerator and the product is supplied with a waste set not verified by test. Maximum operating pressure 10 bar. Maximum operating temperature 60°C

Range of wall mounted two-hole, single outlet (fixed) combination tap assemblies (brass bodies - various finishes). Incorporating a ceramic cartridge headworks and single lever operating member. The spout outlet incorporates an aerator. Maximum working pressure 5.0 Bar. Maximum operating temperature 60°C.

Range of two hole, single outlet, fixed combination tap assemblies, (stainless steel bodies – various finishes) incorporating a ceramic cartridge headwork with a single lever operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C.

Range of two-hole, single outlet, fixed combination tap assemblies, (chrome plated brass bodies) incorporating a non-rising spindle headwork and a thermostatic cartridge that incorporates a manual override button both with either single lever or dome type operating members. The spout outlket incorporates a plastic flow straightener. The products are supplied with metal back nuts. Maximum working pressure 5.0 bar. Maximum operating temperature 65°C.

Range of two-hole, single outlet (fixed) combination tap assemblies (chromium plated brass) incorporating ceramic disc headwork with single lever operating members and manually operated bath/shower diverter. The spout outlets of all models, except XB-SL-038T, incorporate a plastic aerator or flow straightener. Maximum working pressure 10.0 bar. Maximum operating temperature of model XB-SL-038T is 85°C. All other models have a maximum operating temperature of 65°C.

Range of two-hole, single outlet (fixed) combination tap assemblies (chromium plated brass) incorporating ceramic disc headwork with single lever operating members and manually operated bath/shower diverter. The spout outlet incorporates a flow straightener. Maximum working pressure 10.0 bar. Maximum operating temperature 65°C.

Two-hole, single outlet (fixed) combination tap assembly (chromw plated brass body) incorporating quarter turn ceramic disc headworks with single lever operating members and a manually operated diverter to shower outlet. The spout outlet incorporates a plastic flow straightener. The product is supplied with metal back nuts, shower hose and handset. Maximum working pressure 10.0 Bar. Maximum operating temperature 60°C

Range of two-hole, single outlet (swivel) combination tap assemblies with chromium plated brass bodies. Incorporating quarter turn ceramic disc headworks and single lever operating members. The spout outlets incorporate plastic aerators. Maximum working pressure 8.62 Bar. Maximum operating temperature 60.0°C.

Three hole, single outlet (fixed) combination tap assembly (chromium plated brass) incorporating ceramic disc headwork with single lever operating members and a manually operated bath to shower diverter. Maximum working pressure 10.0 bar. Maximum operating temperature 85°C.

Range of three-hole, single outlet (fixed) combination tap assemblies (brass bodies – various finishes). Incorporating a ceramic cartridge headwork with a single lever operating member and self-cancelling diverter to shower outlet. The spout outlet incorporates a plastic aerator. The product is supplied with metal backnuts Maximum working pressure 10.0 Bar. Maximum operating temperature 60 °C

Range of single hole, double outlet (swivel) combination tap assemblies (various finishes) with electronically controlled functions to allow the tap to dispense boiling water, chilled water or sparkling water from under counter units (not supplied or part of this approval) and a ceramic cartridge headwork with single lever operating member controlling the flow of normal mixed water. The spout outlet incorporates a plastic aerator. Maximum working pressure: 5.0 Bar. Maximum operating temperature: 98.0°C.

Range of combined bath filler and/or waste and overflow assemblies (see models) in various finishes. Maximum operating temperature: 60ºC

Range of floor standing, single hole, single outlet (fixed) combination tap assemblies with brass bodies (various finishes), incorporating a ceramic cartridge headwork with a single lever operating member and a manually operated diverter to a shower outlet. The spout outlet incorporates a plastic aerator. Model F9912-** incorporates a single check valve cartridge at the inlet, however, the whole product has not been fully tested to demonstrate that it provides backflow protection. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C

Range of wall mounted bath spout outlets with brass bodies (various finishes) with a plastic aerator incorporated into the outlet. Maximum working pressure: 5 bar. Maximum operating temperature 60°C

Range of wall mounted spout outlets (brass bodies - various finishes) incorporating a plastic aerator. Maximum working pressure 5.0 Bar. Maximum operating temperature 60°C.

Range of shock arrestors comprising of a copper tube and brass adapter. Max working pressure 10.0 Bar. Max working temperature 80°C.

Shock arrestor with stainless steel body. Maximum working pressure 10.0 bar. Maximum operating temperature 100°C

Ranges of cylindrical or tubular expansion vessels with epoxy coated or uncoated steel bodies and either Butyl or EPDM membranes. Maximum working pressure of Tube models is 8.0 bar. All other models have a maximum working pressure of 10.0 bar. Maximum operating temperature 99°C.

Range of carbon block water filters with stainless steel bodies. Maximum operating pressure 6.8 bar. Cold water use only.

Range of plastic pushfit fittings for use with ‘Bevex’ polypropylene pipe. Maximum working pressure 6.5bar. Cold water use only.

Range of “KFLEX SOLID” brass compression fittings, press profile H, TH, F and U, for use with “KFLEX SOLID” multilayers PE-RT/Al/PE-RT pipes. For above ground use only. Maximum working pressure 10.0 bar. Maximum operating temperature 95°C

‘ZL’ range of U profile press fittings (nickel plated brass bodies) for use with ‘ZL’ range of PERT/AL/PERT multi-layered pipes. Maximum working pressure 10.0 bar. Maximum operating temperature 95°C.

NovaTherm range of U profile press fittings (nickel plated brass bodies) for use with NovaTherm range of PERT/AL/PERT multi-layered pipes. Maximum working pressure 10.0 bar. Maximum operating temperature 95°C.

‘HS100’ range of compression fittings with brass, nickel plated brass or DZR bodies for use with copper pipe (manufactured to EN 1057). For above ground use only. Max working pressure 16.0 bar. Max operating temperature 85°C.

FLOMASTA range of polypropolene fittings for use with PE pipe (manufactured to EN 12201). Maximum working pressure 16 bar. Cold water use.

Range of stainless steel press fittings: SS316L stainless steel models are for use with SS316L stainless steel pipe manufactured to EN 10312.; SS304 stainless steel models are for use with SS304 stainless steel pipe manufactured to EN 10312. Crimp joint is achieved by a M profile crimp jaws. For above ground use only. Maximum working pressure 16.0 bar. Maximum operating temperature 85°C.

Range of stainless-steel press fittings (SUS304 or 316L) with EPDM ‘O’-rings for use with stainless-steel pipe (SUS304 or 316L EN 10312), using an ‘M’ press profile. Maximum working pressure 16.0 Bar. Maximum operating temperature 85°C.

Range of system 2000 of flange adaptors and connectors with ductile iron bodies (Blue Epoxy Coated) incorporating EPDM seals. For use with PE pipe manufactured to En 12201 & PVC Pipe manufactured to DIN 8062. Maximum working pressure: 16.0Bar Cold water use only.

Dual flush, WC outlet valve. The valve is operated via a push button assembly for either full or reduced flush and incorporates an internal overflow.

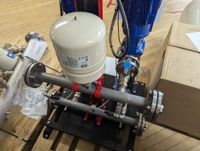

Indirect heat interface unit with copper brazed, stainless-steel heat exchangers, providing heating and instantaneous hot water. The product incorporates an expansion vessel on the cold-water supply to the plate heat exchanger and a safety relief valve on the heating circuit set @ 2.5 bar. The DHW and heating circuits are both fitted with drain valves incorporating cover caps. Maximum working pressure 16 Bar (Primary), 10 Bar (DHW) & 3 Bar (Heating) Maximum operating temperature 95°C

Page 176 of 232

We use cookies to give you the best possible experience with WRAS. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.