Range of UV disinfection units with stainless steel bodies and EPDM seals. The UV lamps are housed inside quartz tubes. Maximum working pressure 10.3 bar. Maximum operating temperature 40°C.

'Celcon M90DW CF2001 Natural'. Natual (appears white), injection moulded POM material. For use with water up to 85°C.

'FY Portland Cement Mortar'. Factory applied, grey coloured Portland cement mortar. Mix cement:sand:water in a 2:1:0.4 mass ratio and apply as per manufacturer's instructions issue reference 'FR20240910', dated '2024-09-10'. Cure for 12 hours@55°C. For use with water up to 65°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

‘NATZINC EP9015 SC PART A-BI.5431’ primer for use with ‘HYDRALFUN AC NOIR PAM -CZL8579’ finish/topcoat. Factory applied, black coloured (once mixed and applied), two-part epoxy primer for use with acrylic coating. Mix base & hardener of primer in a 100:10 weight ratio and apply one coat as per manufacturers TDS ‘NATZINC EP9010 BI 5431’, dated ‘February 2024’. No cure required. Apply one coat of the topcoat as per manufacturers TDS ‘HYDRALFUN AC NOIR PAM CZL8579’, dated ‘July 2018’ and cure for 21 days@23°C. For use with water up to 50°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'Sigmaguard CSF 585/Blue'. Factory applied, blue coloured, two-component, solvent-free epoxy coating. Mix parts A & B in a volume ratio of 77.5:22.5 and apply as per manufacturer's Product Data Sheet '7785', dated 'August 19, 2022'. For use with water up to 50°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'JSGL-SRC (U)'. Factory applied, grey coloured Sulphate resistant cement. Mix cement:sand:water in a 1:1.7:0.4 weight ratio and apply as per manufacturer's Work Instructions 'JSGL/WI/14', issue no, '02', revision no. '00', dated '29.09.2018'. Cure for 24 hours@23°C and then 4 hours@45°C. For use with water up to 65°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'JSGL-OPC (E)'. Factory applied, grey coloured Ordinary Portland cement. Mix cement:sand:water in a 1:1.7:0.4 weight ratio and apply as per manufacturer's Work Instructions 'JSGL/WI/14', issue no, '02', revision no. '00', dated '29.09.2018'. Cure for 24 hours@23°C and then 4 hours@45°C. For use with water up to 65°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'JSGL-OPC (U)'. Factory applied, grey coloured Ordinary Portland cement. Mix cement:sand:water in a 1:1.7:0.4 weight ratio and apply as per manufacturer's Work Instructions 'JSGL/WI/14', issue no, '02', revision no. '00', dated '29.09.2018'. Cure for 24 hours@23°C and then 4 hours@45°C. For use with water up to 65°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'Hydroplate 1914'. Site applied, two-component, white coloured (once mixed and applied) Epoxy-polyamine coating. Mix parts A & B in a 3:1 weight ratio and apply as per manufacturer's Product Data Sheet 'B034', dated 'September 2024'. Cure coat 1 for 48 hours at 15°C. Cure coat 2 for 21 days at 15°C. For use with water up to 50°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mixing and/or curing conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'Grilon TSG-30/4 FA Black 9840'. Black coloured, injection moulded PA material. For use with water up to 85°C.

'Genestar G1350A-M47WF Black'. Black coloured, polyamide 9T material for injection moulding and extrusion purposes. For use with water up to 85°C.

Grilamid LBV-30H FWA natural & black 9225. Grilamid LBV-50H FWA natural & black 9225. Grilamid LBV-65H FWA natural & black 9225. Glass filled (30%, 50% & 65%), injection moulded nylon material available in natural and black colours. For use with water up to 85°C.

'SAFE 10 (H10 + H09, H17 + H04 and N08 + N04)' pipes. Extruded, dual-layered PE pipes comprising of a black coloured inner layer and blue coloured outer layer. Please note that the codes in brackets denote the raw material combinations and only these combinations are approved. In April 2025 ‘H10, H17 & N08’, extruded, single-layered, black coloured PE pipes were added to the approval. Only pipes marked with ‘H10, H17 or N08’ are approved. For use with water up to 40°C.

'BA160E-8229-01'. Black coloured, injection moulded polypropylene material. For use with water up to 85°C.

'WRC EPDM 92645'. Black coloured EPDM liner manufactured by calendaring. Shore hardness 80 A. Tested in-radius size 0.5mm. For use with water up to 23°C.

'ME0940 'O' rings'. Black coloured, injection moulded EPDM rubber 'O' rings. Shore hardness between 40 & 90. Tested in-radii sizes between 1.0mm & 5.0mm. For use with water up to 85°C.

'KF945W, KF955W, KF965W & KF975W'. Black coloured, compression moulded, silicone rubber materials. Shore hardness between 45 & 75. Tested in-radius size 1.0mm. For use with water up to 85°C.

Range of stop valves with plastic bodies. The valves incorporate a built-in solenoid valve which is operated by a switch located on the valve or by a remote control. The leak detector supplied with models SVSM66MRD & SVSM44MRD is not connected to any water pipe, is independent of the valve and is intended to be installed in the area at risk of leakage. It is intended to detect leakage and sends an electrical signal to close the valve. Please note that claims of leak detection have not been verified by WRAS For use with copper pipe (manufactured to BS EN1057), PEX pipe (manufactured to BS7291-3) and PB pipe (manufactured to BS7291 -2). Maximum working pressure 10.0 bar. Cold water use only.

Range of single hole, single outlet (fixed) electronically controlled tap assemblies. Incorporating a solenoid valve activated via an infra-red sensor. The inlets to the control box incorporate stainless steel strainers and the outlet incorporates a plastic aerator. Maximum working pressure: 8 Bar Maximum operating temperature: 65°C

WC flushing cistern incorporating a side entry BS 1212-4 compact type float operated inlet valve providing a Type AG air gap with a dual flush drop valve for full flush volumes of up to 6 litres and a reduced flush of up to 4 litres. The cistern is operated by a manual push button and incorporates a servicing valve on the inlet supply. Maximum working pressure 10.0 bar. Cold water use only.

Range of concealed WC flushing cisterns incorporating a side entry compact type float operated inlet valve providing a Type AG air gap with a dual flush drop valve for full flush volumes of up to 6 litres and a reduced flush of up to 4 litres. The cistern is operated by a manual push button and incorporates a servicing valve and flexible hose on the inlet supply. Maximum working pressure 10.0 bar. Cold water use only.

Range of wall hung concealed WC flushing cisterns with a BS 1212-4 float operated inlet valve providing a Type AG air gap arrangement and a dual flush outlet valve. The flush volume is operated by a push button assembly. Maximum working pressure - 10 Bar. Cold water use only.

Range of single hole, single outlet (fixed) over the rim (swivel nozzle) bidet combination tap assemblies (brass bodies - various finishes), incorporating a ceramic cartridge headworks with a lever type operating member. The spout outlet incorporates a metal aerator. The product is supplied with a lever type pop up waste. Maximum working pressure 3.5 bar. Maximum operating temperature 60°C.

Ceramic cartridge headworks with a plastic body, incorporating silicone seals and NBR O-rings. The product is intended for insertion into specifically dimensioned tap assemblies. Maximum working pressure 10.0 bar. Maximum operating temperature 85°C.

Range of quarter turn Ceramic disc headworks with brass bodies incorporating NBR rubber seals. For insertion into specifically dimensioned bores Maximum working pressure 10.0 bar. Maximum operating temperature 85°C.

Range of ceramic cartridge headworks with plastic bodies. For insertion into specifically dimensioned bores. Maximum working pressure 10.0 bar. Maximum operating temperature 65°C

Range of ceramic disc headworks with brass bodies. For insertion into specifically dimensioned bores. Maximum working pressure 5.0 bar. Maximum operating temperature 85°C.

Range of thermostatic cartridges with either brass or plastic bodies, for insertion into specifically dimensioned bores. Maximum operating temperature 85°C.

Range of single hole, single outlet, (swivel), combination tap assemblies (brass bodies – various finishes), incorporating a ceramic cartridge headwork and single lever operating member. The outlet is a pull-down spray type and incorporates a plastic aerator. Maximum working pressure 8.6 bar. Maximum operating temperature 60°C

Single hole, single outlet (fixed) combination tap assembly (chromium plated brass), incorporating a single sequential cartridge headwork and single lever operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C.

Range of single-hole, single outlet (swivel) combination tap assemblies (brass bodies - various finishes), incorporating ceramic cartridge headworks with single lever operating members. The spout outlets incorporate plastic aerators. Inlets incorporate isolation valves that incorporate single check valve cartridges, however, the complete assembly has not been fully tested to demonstrate it provides backflow protection. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Range of single hole, single outlet (swivel) combination tap assemblies (brass bodies - various finishes), incorporating ceramic cartridge headworks with single lever operating members. The spout outlets incorporate plastic aerators. Inlets incorporate isolation valves that incorporate single check valve cartridges, however, the complete assembly has not been fully tested to demonstrate it provides backflow protection. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Single hole, single outlet (swivel) combination tap assemblies (brass bodies – various finishes), incorporating a ceramic cartridge, non-rising spindle or quarter turn ceramic disc headwork with either a single lever, cross top or dome type operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 Bar Maximum operating temperature 60.0°C

Range of two hole, single outlet, fixed combination tap assemblies, (stainless steel bodies – various finishes) incorporating a ceramic cartridge headwork with a single lever operating member. The spout outlet incorporates a plastic aerator. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C.

two-hole, single outlet (fixed) combination tap assembly (chromium plated brass), incorporating a quarter turn ceramic disc headwork controlling the flow using a dome type operating member. Temperature is controlled via a thermostatic cartridge also using a dome type operating member with a manual override button, and the product also incorporates a manual diverter to shower outlet. The inlets incorporate a stainless-steel strainer and an approved check valve cartridge however, the complete product has not been fully tested to demonstrate it provides backflow protection. The spout outlet incorporates a plastic aerator. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Range of two-hole, single outlet (fixed) combination tap assembly with brass body various plating), incorporating quarter turn ceramic disc headworks with single lever operating members and a self cancelling diverter to the shower outlet. The spout outlet is a waterfall type. Maximum working pressure 10.0 Bar Maximum operating temperature 65.0°C

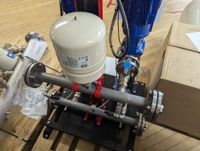

Ranges of cylindrical or tubular expansion vessels with epoxy coated or uncoated steel bodies and either Butyl or EPDM membranes. Maximum working pressure of Tube models is 8.0 bar. All other models have a maximum working pressure of 10.0 bar. Maximum operating temperature 99°C.

Range of cylindrical expansion vessels with epoxy coated or uncoated steel bodies and Butyl membranes. Maximum working pressure 10.0 Bar (15.0 bar INOX PRO 0.16L). Maximum operating temperature 99.0°C.

Filling loop assembly, incorporating a stainless-steel braided EPDM lined flexible hose assembly, an isolation valve (DZR brass body) and a combined isolation valve and non-verifiable double check valve assembly (DZR brass body) which incorporates 2 check valve cartridges, verified by test (suitable for backflow protection against Fluid Category 3). Maximum working pressure 10.0 bar. Maximum operating temperature 85°C.

Range of shower and tap filters with plastic bodies. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C

Range of “KFLEX SOLID” brass compression fittings, press profile H, TH, F and U, for use with “KFLEX SOLID” multilayers PE-RT/Al/PE-RT pipes. For above ground use only. Maximum working pressure 10.0 bar. Maximum operating temperature 95°C

Range of “JRG Sanipex MT” compression fittings for use with “JRG Sanipex MT” multilayer pipes (PE-Xc/Al/PE-Xb 16x2,25mm to 40x3,5mm and PE-Xc/Al/PE-Xc 50x4,0mm and 63x4,5mm). Maximum working pressure 10.0 bar. Maximum operating temperature 85°C for dimensions 16x2,25 mm to 40x3,5 mm. Maximum operating temperature 60°C for dimensions 50x4,0 mm and 63x4,5 mm.

Range of CU type press copper crimp fittings with EPDM ‘O’-rings for use with copper tube manufactured to EN 1057. The joints are achieved by means of a crimping tool. For above ground use. Maximum working pressure: 16.0 bar. Maximum operating temperature: 85°C

‘Tweetop LBP system’ consisting of brass bodied press fittings for use with ‘Tweetop multilayer pipe’ PE-RT II/AL/PE-RT II. The press fitting is achieved by use of a press fitting tool (‘U’ or ‘TH’ crimping profiles). Maximum working pressure: 10.0 Bar. Maximum working temperature: 95°C.

Instinct range of U profile press fittings (nickel plated brass bodies) for use with Instinct range of PERT/AL/PERT multi-layered pipes. Maximum working pressure 10.0 bar. Maximum operating temperature 95°C.

‘HS100’ range of compression fittings with brass, nickel plated brass or DZR bodies for use with copper pipe (manufactured to EN 1057). For above ground use only. Max working pressure 16.0 bar. Max operating temperature 85°C.

Range of stainless steel press fittings: SS316L stainless steel models are for use with SS316L stainless steel pipe manufactured to EN 10312.; SS304 stainless steel models are for use with SS304 stainless steel pipe manufactured to EN 10312. Crimp joint is achieved by a M profile crimp jaws. For above ground use only. Maximum working pressure 16.0 bar. Maximum operating temperature 85°C.

Range of stainless-steel press fittings (SUS304 or 316L) with EPDM ‘O’-rings for use with stainless-steel pipe (SUS304 or 316L EN 10312), using an ‘M’ press profile. Maximum working pressure 16.0 Bar. Maximum operating temperature 85°C.

Range of copper crimped fittings with EPDM ‘O’-rings for use with copper pipe manufactured to EN1057. For above and below ground use. Maximum working pressure 16 Bar. Maximum operating temperature 99°C.

DMFit range of black, grey and white plastic pushfit fittings for use with DM LLDPE pipes or PEX barrier pipe manufactured to BS7291-3. (White fittings were added to the approval in August 2025). When used with DM LLDPE tubing the supplied black or grey pipe inserts (ATS) must be installed. When used with PEX barrier pipe the supplied beige pipe inserts must be installed. DM LLDPE tubing are available in black, natural (appearance is white), white, red, and blue colours. Maximum working pressures and temperatures: When used with DM LLDPE tubing: 4-15mm & 5/32”-½” pushfit sizes: 12.0 bar, cold water use only. 6-15mm & ¼”-½” pushfit sizes: 7.0 bar @ 65°C. When used with PEX Barrier pipe (manufactured to BS7291-3): 15-22mm pushfit sizes: 12.0 bar, cold water use only and 7.0 bar @ 65°C. Fittings which incorporate 4-10mm & 3/16” - ⅜” barb connections: 12.0 bar, cold water use only. Fittings which incorporate ½” - ¾” barbed end connections are open outlet use only. Maximum operating temperature 65°C.

Page 65 of 86

We use cookies to give you the best possible experience with WRAS. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.