`BFSC MAS S&MDN 20`. Factory applied, grey coloured, blast furnace slag cement mortar. Mix sand and cement in a mass ratio of 2.35:1. Add water to give a mass ratio of 1:0.45 (cement:water). Cure first time for 7 hours@70°C. Cure second time for 12 hours@70°C. For use with water up to 60°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mix and/or cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

'Flogul® 645 Bleu 5005 (blue coloured) & Flogul® 645 Noir (black coloured)'. Factory applied, PVDC coatings to be applied in accordance with manufacturer's data sheet dated '11/09/2018'. Cure for 7 days@20°C. Flogul® 645 Bleu 5005 is for use with water up to 23°C. Flogul® 645 Noir is for use with water up to 60°C. These materials are only approved for the curing conditions that appear on the approval. If the cure conditions are varied from those specified on the approval then the materials are not covered by the scope of the approval.

'Edelpoxy FN 132 Blue Coating'. Factory applied, blue coloured epoxy coating. Apply as per manufacturer's instructions dated 'January 28, 2020'. Cure for 7 days@30°C. For use with water up to 85°C. This material is only approved for the curing conditions that appear on the approval. If the cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

'JSP/SF-Blue'. Factory applied, blue coloured epoxy powder coating. Apply as per manufacturer's TDS 'SF-D0001' dated 2021.01.01. Cure for 10 minutes@200°C. For use with water up to 85°C. This material is only approved for the curing conditions that appear on the approval. If the cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

'Eco-Coat FBE Powder PFC/7017'. Factory applied, blue coloured epoxy powder coating. Apply as per instructions for use 'Doc/PFC/703'. Cure for 2.5 minutes@235°C (metal temperature). For use with water up to 85°C. If the cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

'LDP-800 (1009GBSDT)' - white coloured & 'LDP-800' - blue coloured. Factory applied, fusion bonded epoxy powder coatings. Apply as cure as per manufacturer's user instructions file no. 'NP200917', 'version 1', dated 'Sep, 17, 2020'. For use with water up to 85°C.

'RUNBAO Epoxy resin coating 5017' (light blue), 'RUNBAO Epoxy resin coating 5005' (blue) & 'RUNBAO Epoxy resin coating 3016' (red). Factory applied electro-statically sprayed epoxy resin coating. Apply and cure as per manufacturer's instructions version 'YZRB-2015V1.0' dated '2015-06-01'. Between January 2021 and 9th December 2021, the materials were suitable for use with water up to 23°C. Between 10th December 2021 and 31st January 2026, the materials are suitable for use with water up to 85°C.

'Intercrete 4807'. Site applied, grey coloured cementitious repair mortar. Mix 'Intercrete 4807' and water in a mass ratio of 9.4:1 Cure for 21 days@7°C. For use with water up to 23°C. This material is only approved for the curing conditions that appear on the approval. If the cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

'YHCM-01'. Factory applied, grey coloured sulphate resisting cementitious mortar. Mix sand, cement & water in a ratio of 1: 2.5: 0.3. Cure for 4 hours@20°C. For use with water up to 60°C. This material is only approved for the mixing and curing conditions that appear on the approval. If the mix and/or cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

`Yorkshire Flux 130 (White)`. White coloured paste flux. For use with water up to 85°C.

'OCPOL 611'. Beige coloured (translucent), Isophthalic Unsaturated Polyester Resin with glass fibre material manufactured using hand-lay method. For use with water up to 70°C.

'OCPOL N 7180 E'. Grey coloured (translucent), Isophthalic Unsaturated Polyester Resin with glass fibre material manufactured using hand-lay method. For use with water up to 70°C.

'ResinTech CG10-F-UPS'. Gold coloured ion exchange resin. For use with water up to 65°C.

'Seplite LSF 978 and Seplite Monojet LSF 9780'. Amber coloured ion exchange resins. For use with water up to 85°C.

'Bluesil Paste 408'. White coloured, translucent silicone paste lubricant. Apply as per manufacturer's instructions. For use with water up to 85°C.

'Krytox™ Oils; GPL 104, 143AB, VPF 1525, VPF 1531, AUT 1045, GPL 105, GPL 106, 143AC, 143AD & GPL 107'. Clear (colourless), perfluoropolyether oils. 'Krytox™ Greases; GPL 204, 240AB, AUT 2045, GPL 205, GPL 206, 240AC, 240AD & GPL 207'. White coloured, Polytetrafluoroethylene thickened perfluoropolyether greases. All are suitable for use with water up to 85°C.

'RP380s & RP361'. Off-white coloured (opaque) silicone greases. Apply as per manufacturer's instructions. For use with water up to 65°C.

'PA66+50%GF 1620G50 BK015'. Black coloured, injection moulded PA66 (with 50% glass fibre) material. For use with water up to 85°C.

Grilamid L 20 H FWA natural & Grilamid L 20 H FWA black 9225. Grilamid L 25 H FWA natural & Grilamid L 25 H FWA black 9225. Injection moulded, natural (appears white) or black coloured, PA materials. For use with water up to 85°C.

'LATILUB 75/4-20T NT:0080F2'. White coloured, injection moulded PBT material. For use with water up to 85°C.

'Siropol 8340'. Red coloured, injection moulded polyester resin. For use with water up to 45°C.

'GF PE100 Pipe (product codes beginning with '20014Y')'. Black coloured (with blue external stripes), extruded polyethylene pipe. For use with water up to 23°C.

'3301 black (330160415BLK)'. '3301 black (330130415BLK)' was added to the approval in November 2023. Black coloured, single sided polyethylene foam tapes with acrylic adhesive system. For use with water up to 23°C.

`Como-Pex Pipe`. Extruded, white coloured HDPE pipe. In April 2024, `Como-Pex Pipe`, extruded, black coloured HDPE pipe was added to the approval. Both pipes are for use with water up to 85°C.

‘Union Pipes Industry – K.S.A. HDPE Pipe’, manufactured from ‘P6006’ by Union Pipes Industry Co. Ltd, Rabigh, Saudi Arabia. Black coloured, extruded HDPE pipe. For use with water up to 60°C.

'BORFIT HDPE fittings'. Black coloured, injection moulded HDPE fittings. For use with water up to 60°C.

'XYRON WG732 AWY2266, WG732 AWY2269, WG732 AWY6628, WG722 AWY6627, W5002 AWY1208, W5002 AWY2267, W5002 AWY6629, W5002 AWY3326, WG722 AWY2261, WG732 AWY3325, WG722 AWY3324 & WG733 ABY3315'. Injection moulded, black, grey or beige coloured PPE materials manufactured in Thailand & China. For use with water up to 85°C.

'Ryton XE-5501BL'. Dark grey coloured, injection moulded PPS material. For use with water up to 23°C.

'Ryton XE5030BL'. Black coloured, injection moulded PPS material. For use with water up to 85°C.

'ALTECH PP-H FC 3013/500.01 GB13 NC0001-00 (1004864600000)'. Natural (appears white coloured), injection moulded PP-H material. For use with water up to 50°C.

`Aqua-Plus Fiberglass triple layered PP Pipe`. Extruded, triple layered pipe consisting of a green coloured, polypropylene inner layer, grey coloured glass fibre middle layer and green coloured, polypropylene outer layer. For use with water up to 70°C.

`Aqua-Plus Pipe`. Green coloured, extruded polypropylene pipe. For use with water up to 70°C.

'Hostalen PP H1022 12 (black coloured) & Hostalen PP H1022 (natural - appears white in colour)'. Injection moulded and compression moulded PP materials. For use with water up to 23°C.

`Superfast Copper`. Site applied, copper coloured epoxy putty. The putty should be kneaded together, its supplied in a pre-measured 1:1 mass ratio and applied as per manufacturer's directions for use dated August 9th, 2021. Cure for 24 hours@22°C. For use with water up to 23°C. This material is only approved for the curing conditions that appear on the approval. If the cure conditions are varied from those specified on the approval then the material is not covered by the scope of the approval.

‘PX70N-0201 washers, ‘O’ rings, bushes gaskets & discs’. Black coloured, injection moulded EPDM components with a shore hardness of 70. The washers have a tested in-radius size of 3.0mm. The ‘O’ rings have a tested in-radius size of 3.5mm. The bushes gaskets have a tested in-radius size of 2.0mm. The discs have a tested in-radius size of 2.65mm. All are for use with water up to 85°C.

`EP1/1/5 BLK 'O' rings, seals & gaskets'. Black coloured, injection moulded EPDM 'O' rings, seals & gaskets. Shore hardness 70. The 'O' rings & gaskets have a tested in-radius size of 1.5mm. The seals have a tested in-radius size of 0.8mm. For use with water up to 85°C.

'EPDMprx'. Black coloured, injection moulded EPDM material. Shore hardness 78. Tested in-radius size 1.0mm. For use with water up to 85°C.

'60 EPDM 334 black 60 ShA' (shore hardness 60) and '70 EPDM 335 black 70 ShA' (shore hardness 70). Black coloured compression moulded EPDM materials. Tested in-radius 1.07mm. For use with water up to 85°C.

'WRC-70 'O' rings and gaskets'. Black coloured, injection moulded NBR rubber 'O' rings and gaskets. Tested in-radius size between 0.5mm & 2.6mm. Shore hardness 70. For use with water up to 23°C.

‘40SIL310P, 45SIL310P, 50SIL310P(W), 55SIL310P, 60SIL310P, 65SIL310P, 70SIL310P, 75SIL310P & 80SIL310P'. Compression moulded, silicone rubber ‘O’ rings in natural, white, black, red, blue & yellow with tested in-radii sizes of between 0.5mm & 3.4mm. For use with water up to 85°C.

'1922, 1923 & 1933 washers'. Red coloured, injection moulded silicone rubber washers. 1923 washers have an in-radius of 1.59mm. 1933 washers have an in-radius of 0.83mm. 1922 washers have an in-radius of 1.23mm. For use with water up to 85°C.

'XR0130012 (30SH), XR0140012 (40SH), XR0150012 (50SH), XR0160012 (60SH) & XR0170012 (70SH)'. Translucent, colourless, compression moulded silicone rubber materials. Shore hardness between 30 & 70. Tested in-radius size 1.5mm. For use with water up to 85°C.

Floor mounted, single hole, single outlet (fixed) combination tap assembly (chromium plated brass), incorporating a ceramic cartridge headwork with single lever operating member and a lockable diverter to shower outlet. The spout outlet incorporates a plastic aerator. The product is supplied with a shower hose and handset. Both the shower outlet (from the main body) and the inlet to the shower handset incorporate an approved check valve cartridge, however, the complete product has not been fully tested to demonstrate it provides backflow protection. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C.

Bidet seat assembly which discharges via a sensor actuated solenoid valve and utilises a type `AB` airgap (verified by test - suitable for backflow protection against fluid category 5). The inlet incorporates a strainer and flow regulator. Maximum working pressure 10.0 bar. Cold water supply only.

Range of deck mounted, electronically operated combination tap assemblies (chromium plated brass). The flow is controlled by a solenoid valve which is actuated via an infrared sensor on the spout. The spout outlet incorporates a plastic aerator. Maximum working pressure 8.0 bar. Maximum operating temperature 60°C.

Side entry BS1212-4 (2016) compact type float operated valve for WC flushing cisterns. Maximum working pressure 10.0 bar. Cold water use only.

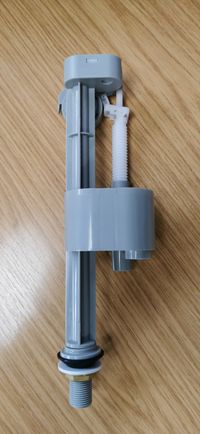

Range of bottom entry BS1212-4 (2016) compact type float operated valve for WC flushing cisterns. The inlet incorporates a plastic strainer. Maximum working pressure 10.0 Bar. Cold water use only.

WC flushing cistern incorporating a bottom entry BS1212-4 (2016) compact type float operated inlet valve providing a Type AG air gap with a dual flush drop valve for full flush volumes of up to 6 litres and a reduced flush of up to 3 litres. The cistern is operated by a pnuematic push button. Maximum working pressure 10.0 bar. Cold water use only.

Range of concealed WC cistern in white plastic incorporating a BS 1212-4:2016 side entry float operated inlet valve providing a Type AG air gap arrangement and a single or dual flush outlet valve. The full flush can be set at 6 litres and the reduced flush can be set at 3 litres. The inlet supply incorporates a servicing valve. Maximum operating pressure 10.0 bar. Cold water use only.

Range of concealed WC cistern in white plastic incorporating a BS 1212-4:2016 side entry float operated inlet valve providing a Type AG air gap arrangement and a single or dual flush outlet valve. The full flush can be set at 6 litres and the reduced flush can be set at 3 litres. The inlet supply incorporates a servicing valve. Maximum operating pressure 10.0 bar. Cold water use only.

Page 19 of 234

We use cookies to give you the best possible experience with WRAS. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.