‘E-WATER BLOCK’ self-closing valves with black plastic bodies and stainless-steel filters. Maximum working pressure 10.0 bar. Maximum operating temperature 60°C.

Copper corrugated hose. Maximum working pressure 10.0 bar. Maximum working temperature 90°C.

Range of plastic bodied quarter turn isolation valves, with EPDM rubber ‘O’-rings, seals and washers. The 52.009.100 model is operated by a hex key (not supplied), the 52.009.200 model is operated by a key (supplied). Maximum working pressure 10.0 bar. Maximum operating temperature 90°C.

Appliance inlet group assembly comprising of EPDM gaskets, a plastic bodied Y-pattern strainer, ¾” BSP (F) x ½” BSP (F) brass adaptor, a chrome plated DZR brass bodied double check valve assembly (suitable for backflow protection against Fluid Categry3), a ½” BSP (F) x ¾” BSP (M) brass adaptor, a dual layer hose with a PVC outer (grey) and PVC liner (black), a solenoid valve which incorporates a plastic strainer and a flow regulator within the inlet. Maximum working pressure 6.0 bar. Maximum operating temperature 60°C.

Range of water meter couplings with black plastic bodies. Maximum working pressure 16.0 bar. Cold water use only

Appliance inlet group assembly comprising of an EPDM gasket, ¾” BSP (F) x ½” BSP (F) brass adaptor, a chrome plated DZR brass bodied double check valve assembly (suitable for backflow protection against Fluid Categry3), a ½” BSP (F) x ¾” BSP (M) brass adaptor, a flexible reinforced hose assembly with a PVC lining and a solenoid valve which incorporates a plastic strainer and a flow regulator within the inlet. Maximum working pressure 5.0 bar. Cold water use only.

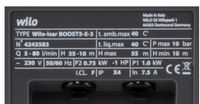

Range of booster pumps with stainless steel bodies and impellers (AISI 304: AL-RED models or AISI 316: CP models), EPDM ‘O’-rings and a ceramic/graphite/EPDM shaft seal. Maximum working pressure: CP(m) 100-130-132-150-158 and AL-RED(m) 600-610-620 models: 6.0 bar. All other models: 8.0 bar. Maximum operating temperature 90°C.

Centrifugal pump with a plastic body, plastic impellers and NBR ‘O’-rings. The product includes an (integral) expansion vessel and the inlet incorporates a non-return valve (not suitable for backflow protection). Maximum working pressure 4.5 bar. Maximum operating temperature 50°C.

Single pump units with plastic bodies and impellers, EPDM ‘O’-rings, expansion vessel with an EPDM membrane and a carbon graphite/ceramic/NBR shaft seal (bt-ar 13 bx 4ff xp). Each pump inlet incorporates a non-return valve. Maximum working pressure 10.0 bar. Cold water use only.

Range of shower outlets with brass or stainless steel bodies (chrome plated) fitted with NBR ’O’-rings. Maximum operating temperature 65°C.

Range of shower arms with a brass body and various finishes. Maximum operating temperature 60°C.

Range of shower handsets with plastic bodies and EPDM ‘O’-rings. Maximum operating temperature 65°C.

Range of wall mounted compact shower panels with push button timed flow control. The inlet incorporates a plastic flow regulator and a stainless-steel strainer. Maximum working pressure 4.0 Bar Maximum operating temperature 60°C

Concealed installation set for use with wall mounted overhead shower outlets (brass body – various finishes). The inlet to the shower outlet incorporates a stainless-steel strainer, a plastic flow regulator and an approved check valve cartridge, however, the complete product has not been fully tested to demonstrate it provides backflow protection. Maximum operating temperature 60°C.

Range of shower arms and outlets with chrome plated brass bodies. The shower outlets incorporate plastic flow regulators at the inlets. Maximum operating temperature 85°C.

Range of shower hoses and handsets (various finishes - see model) with EPDM ‘O’-rings. Maximum operating temperature 60°C.

Range of Y pattern strainers with a bronze body and stainless steel mesh. Maximum working pressure 20.0 bar. Maximum operating temperature 85°C.

Pillar tap incorporating a ceramic cartridge headwork (chrome plated brass body) with a single lever operating member. The spout outlet incorporates a flow straightener and flow regulator. The product is supplied with plastic backnuts Maximum working pressure 10 bar. Maximum operating temperature 60°C

Range of pillar taps with brass bodies (various finishes - see model) incorporating quarter turn ceramic disc headworks with single lever operating members. The spout outlet incorporates a plastic flow straightener. The 4102BD18 models incorporate a plastic flow restrictor on the inlet. The products are supplied with plastic and brass backnuts. Maximum working pressure 10.0 bar. Maximum operating temperature 65°C.

Range of pillar taps with brass bodies (various finishes), incorporating quarter turn ceramic disc headworks with either cross top or single lever operating members. The spout outlet incorporates a plastic flow straightener. The product is supplied with metal backnuts. Maximum working pressure 5.0 bar. Maximum operating temperature 60°C.

Page 73 of 582

We use cookies to give you the best possible experience with WRAS. Some are essential to provide website functions and ensure the website is secure. We also use cookies to help us understand how people use the site and to make improvements. Click "Accept All" to enable recommended settings or click "Manage cookies" to adjust your settings. For more details, see our Cookie Policy.